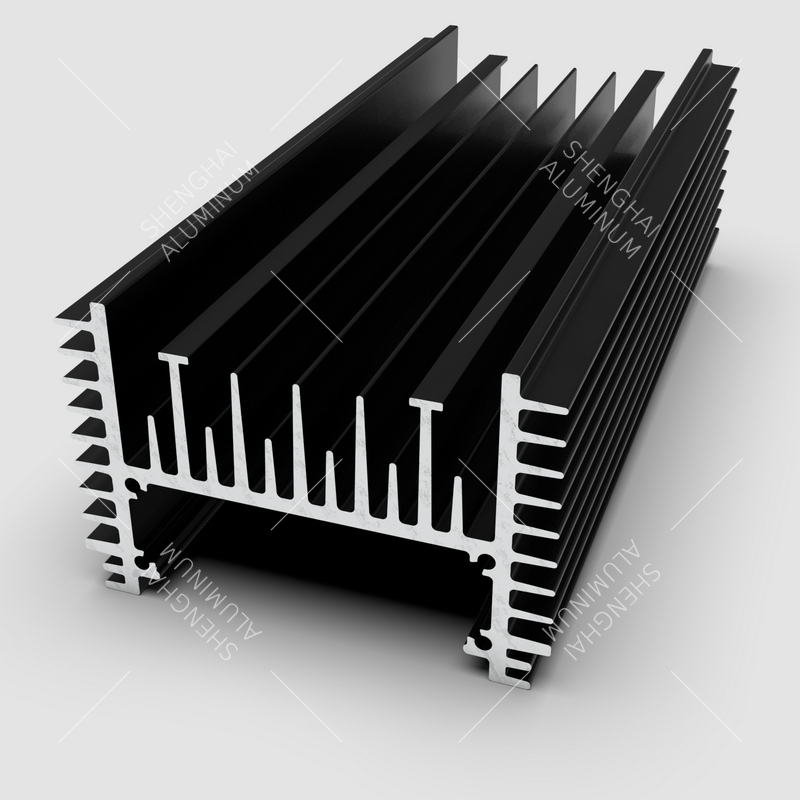

The heat dissipation effect of LED aluminum profile heat sink directly relates to the service life of LED lamps and lanterns.

LED light-emitting diodes, a new generation of solid-state light sources, have many advantages such as long life, high efficiency and energy saving, green and environmental protection, etc. They are widely used in the field of display and lighting. With the development of science and technology, advanced technology is constantly applied in the production of semiconductors to improve the luminous efficiency of LED continuously and the cost continues to drop.

Although LED lights have many advantages, the current LED lights are only 20-30% of the electrical energy into light energy, and the remaining 70 – 80% is converted into heat. This generated heat greatly impacts the life of the LED, luminous efficiency, and a great impact.

According to the test, let’s look at the use of LEDs at various temperatures.

Junction temperature (Celsius) 1501251007550 life (hours) 600010500195003900090000

As seen from the table, it is generally believed that the temperature of LED lights should not exceed 80 degrees. 60-70 is an ideal environment for use, while in the natural environment is difficult to do; let’s look at the actual application of the use of street lights using LED light source: A domestic city for a period of three months of testing, the results found that the test LED lights in the use of the attenuation degree of: 8.77%, the 15.5%, 20.4%. There is such a large degree of attenuation because these street lights work at a temperature of more than 80 degrees. That is, there are problems with heat dissipation.

How to calculate how much heat sink should be used according to the power of LED lights?

According to the actual experiment, the following results can be obtained.

For 1W high-power LED white light, the total effective heat sink surface area should be between 50-60 square centimetres. For 3W products, the recommended total effective heat sink surface area should be about 150 cm2. The existing mainstream LED profile heat sink technology is still through the aluminum heat sink to heat dissipation, and for some of the more powerful lights may not meet the requirements of ordinary aluminum profile, then the heat sink will be modified, such as in the heat sink and heat source only see to increase the thermal conductivity of the rubber gasket or thermal grease, in order to increase the thermal conductivity and improve the efficiency of heat dissipation, sometimes the bottom of the heat sink will be added to the copper sheet to increase the efficiency of heat conduction. Improve the service life and efficiency of LED lamps.