When selecting aluminum for extrusion or structural projects, one of the most common questions is: What is stronger, 6061 or 6063 aluminum?

Both alloys belong to the 6xxx aluminum series and contain magnesium and silicon as their main alloying elements. However, they are designed for different applications. Understanding their strength, appearance, and processing performance will help you choose the right material for your project.

What Is 6061 Aluminum Used For?

6061 aluminum is a high-strength structural alloy. It is widely used in projects where the material must carry weight, resist stress, and maintain durability.

Because of its strength and good machinability, 6061 is commonly used for:

- Structural frames

- Solar mounting systems (heavy-duty types)

- Industrial equipment

- Automotive and truck components

- Marine parts

- CNC machined aluminum products

- Platforms, ladders, and support structures

If your product needs load-bearing capacity and mechanical strength, 6061 is usually the better option.

What Is 6063 Aluminum Used For?

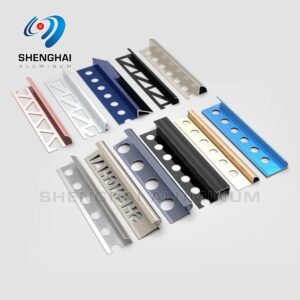

6063 aluminum is known as an architectural aluminum alloy. It is not as strong as 6061, but it has a much smoother surface, better extrusion performance, and excellent anodizing results.

This makes it ideal for products where appearance and profile complexity matter.

Typical applications include:

- Aluminum doors and windows

- Curtain wall systems

- Furniture aluminum profiles

- Cabinet and wardrobe handles

- LED aluminum profiles

- Decorative trims and partitions

- Railings and display frames

If your project requires a clean surface finish and complex extrusion shapes, 6063 is the preferred choice.

Strength Difference Between 6061 and 6063 Aluminum

The biggest difference between these two alloys is strength.

In the common heat-treated condition:

- 6061-T6 tensile strength is about 290 MPa

- 6063-T5 tensile strength is about 160 MPa

- 6063-T6 tensile strength is about 205 MPa

This means 6061 aluminum is significantly stronger than 6063 aluminum.

In real applications:

Use 6061 for structural and heavy-load parts

Use 6063 for architectural and decorative profiles

So the question is not only “which is stronger,” but which one fits your product better.

When Should You Choose 6061 Aluminum?

6061 aluminum is the right choice when your product needs:

- High strength and rigidity

- Load-bearing performance

- Good fatigue resistance

- Machining and drilling operations

- Thick or simple structural shapes

Typical scenarios include:

- Solar mounting structures that carry heavy panels

- Industrial frames and equipment bases

- Transportation components

- Marine structures

In these cases, strength is more important than surface appearance.

When Should You Choose 6063 Aluminum?

6063 aluminum is better when your product needs:

- Smooth and clean surface finish

- High-quality anodizing or powder coating

- Thin walls and complex extrusion shapes

- Lightweight architectural profiles

- Decorative appearance

It is widely used for:

- Doors and window frames

- Curtain walls

- Furniture and cabinet profiles

- LED heat sink housings

- Interior decorative aluminum trims

In these applications, appearance and extrusion quality matter more than maximum strength.

How to Choose 6061 or 6063 Aluminum

When choosing between 6061 aluminum and 6063 aluminum, the key is to match the alloy to your application. If your project requires high strength, load-bearing capacity, or CNC machining, such as solar mounting structures, industrial frames, or transportation components, 6061 aluminum is the better option because it offers superior mechanical performance and durability. If your focus is on smooth surface finish, complex extrusion shapes, and high-quality anodizing, such as aluminum doors and windows, curtain walls, furniture profiles, or LED housings, then 6063 aluminum is more suitable due to its excellent extrudability and aesthetic results. In simple terms, choose 6061 for strength and structural use, and choose 6063 for architectural appearance and precision extrusion to achieve the best balance between performance, cost, and manufacturing efficiency.

6061 aluminum is stronger than 6063 aluminum, making it ideal for structural and load-bearing applications.

6063 aluminum is better for surface finishes, anodizing, and architectural extrusion, making it the top choice for doors, windows, furniture, and decorative profiles.

The best alloy depends on your strength requirements, design complexity, surface expectations, and manufacturing process.

At Shenghai Aluminum, we provide both 6061 and 6063 aluminum extrusion solutions for solar systems, industrial structures, architectural projects, and furniture profiles. Our team helps customers choose the right alloy to achieve the best balance between strength, appearance, and cost, ensuring reliable performance for every application.