The best material for tile trim depends on various factors, including your design preferences, the location of the tiles, and your budget. Here are some common materials used for tile trim:

Metal Trim:

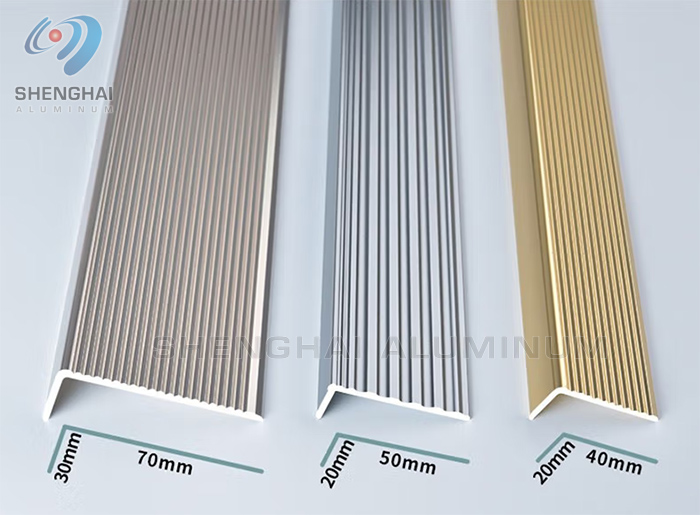

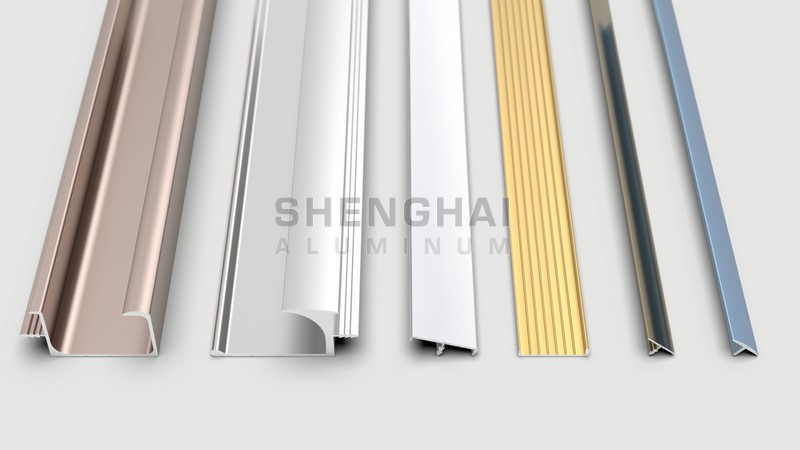

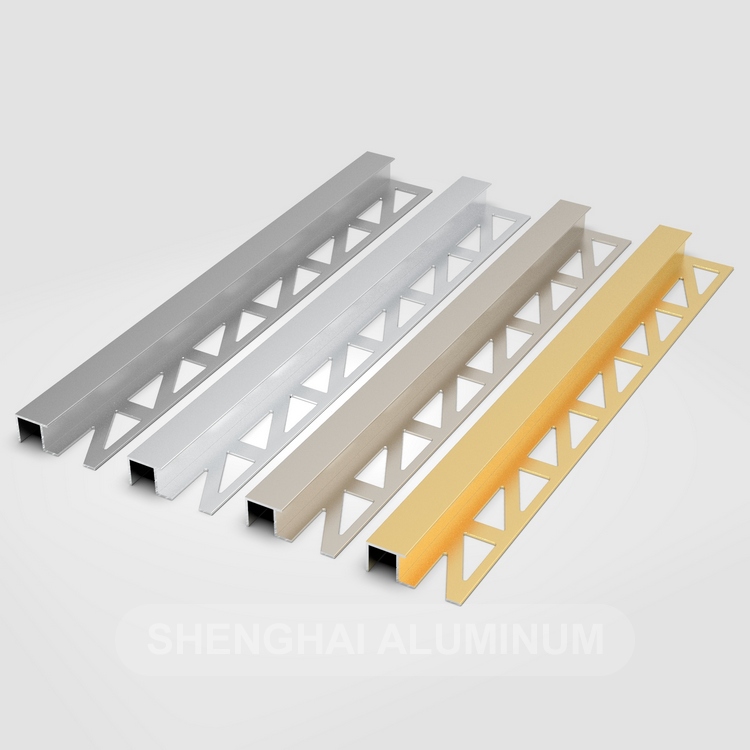

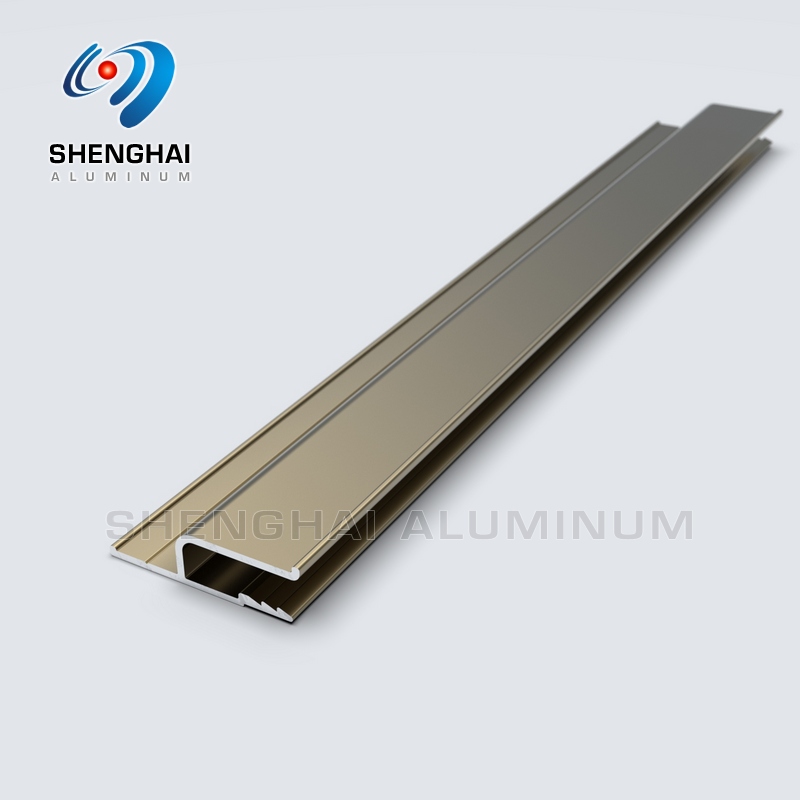

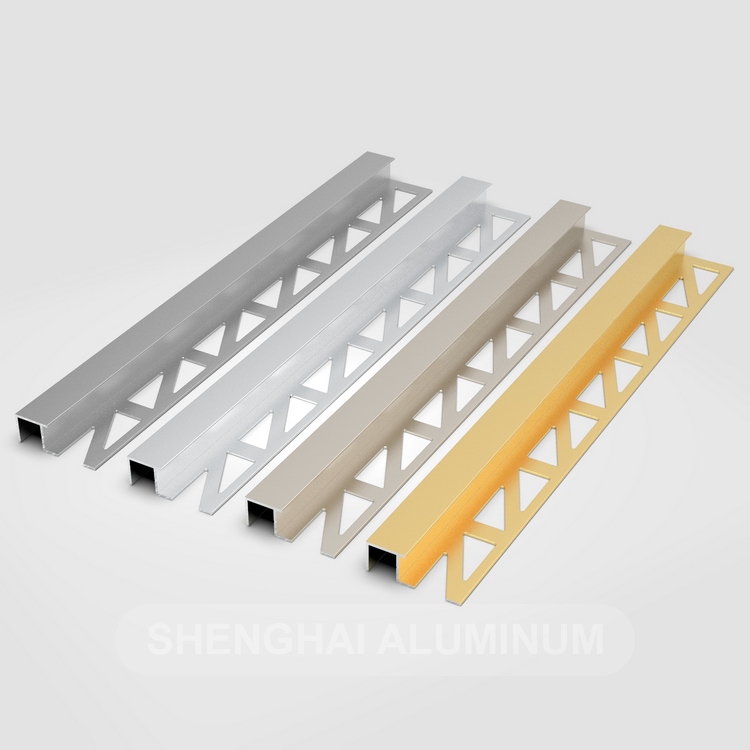

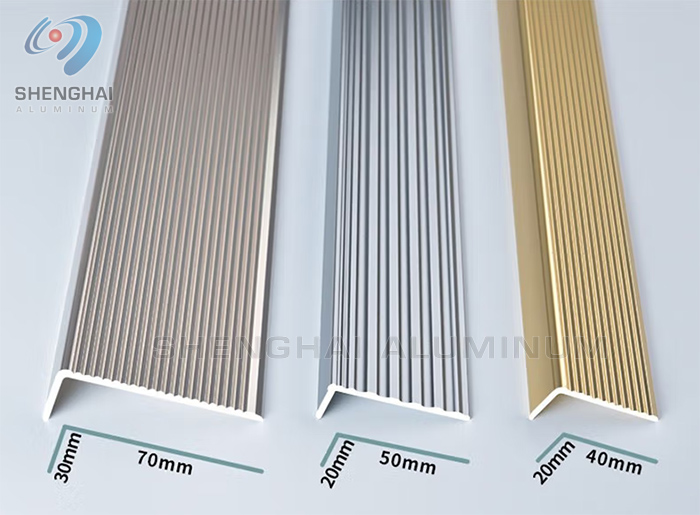

Aluminum: Aluminum tile trim is popular due to its durability, corrosion resistance, and lightweight nature. It is available in various finishes, such as brushed, polished, or anodized, to complement your tile design.

Stainless Steel: Stainless steel trim is known for its corrosion resistance and strength. It’s an excellent choice for high-traffic areas or places exposed to moisture.

PVC Trim:

PVC tile trim is a cost-effective option. It is easy to install and resistant to moisture and corrosion. However, it may not be as durable as metal options.

Schluter Strips:

Schluter strips, like the Schluter Systems, are made of various materials, including metal and plastic. They are designed specifically for edge protection and finishing in tile installations. They offer a sleek, finished look.

Quarry or Bullnose Tiles:

In some cases, using tiles with a finished edge (quarry or bullnose tiles) eliminates the need for separate trim pieces.

Wood Trim:

Wood trim can be used as an alternative in specific settings where a natural or rustic look is desired. It’s commonly used for decorative purposes in non-wet areas.

Glass Trim:

Glass tile trim can add a modern and sophisticated touch to your design. However, it is not as durable as metal or PVC options and is generally used in non-high traffic areas.

The choice of material also depends on the location of the tiles. For example, in wet areas like bathrooms or kitchens, it’s crucial to choose a trim that is moisture-resistant and won’t corrode over time. In high-traffic areas, durability is a key consideration. Your personal style and the overall design of the space should also influence your choice.

Ultimately, the “best” material for tile trim is subjective and dependent on your specific needs and preferences. In general, aluminum trim for tiles are currently highly favored. Their resistance to wear and exceptional appearance make them the preferred choice for a wide range of customers.