Aluminum trim is a type of trim material that is made from aluminum. It is used for finishing, trimming and edging various types of building materials such as windows, doors, roofing, siding, and decking. Aluminum trim is a popular choice for its durability, versatility, and low maintenance requirements. It is also lightweight and weather-resistant, making it ideal for use in both indoor and outdoor applications.

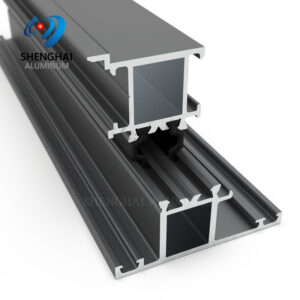

Some of the common types of aluminum trim include corner trim, J-trim, L-trim, U-trim, and window trim. These trims are available in a variety of sizes, shapes, colors, and finishes to match the aesthetic of any building project.

In addition to its decorative purposes, aluminum trim can also provide functional benefits such as protecting the edges of building materials from damage, covering gaps and seams, and improving the overall energy efficiency of a building.

Types of aluminum trim

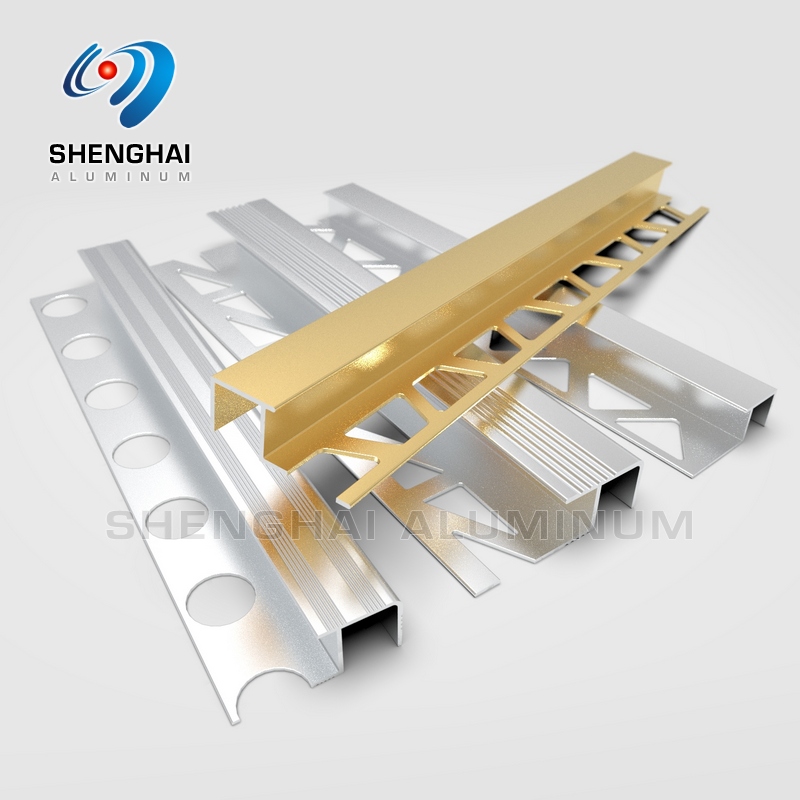

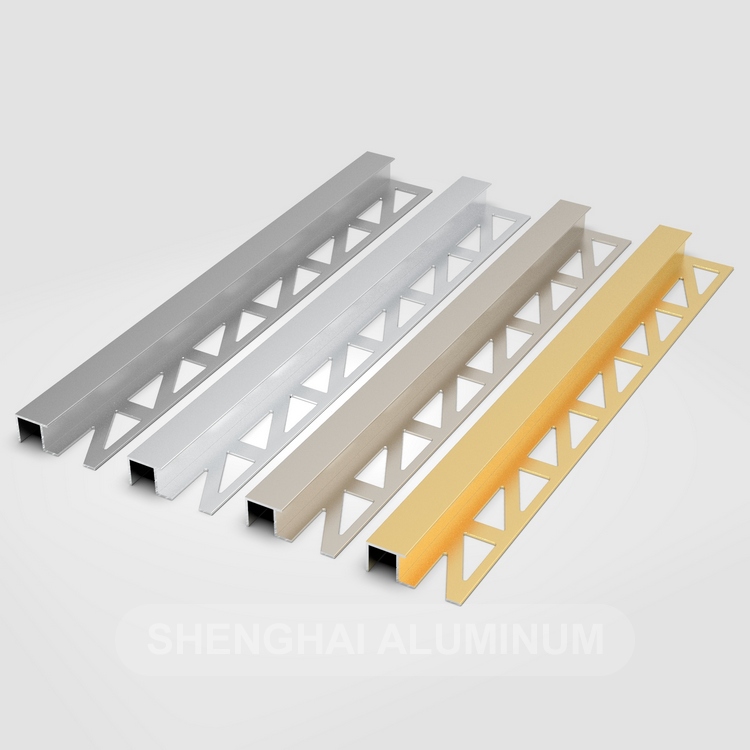

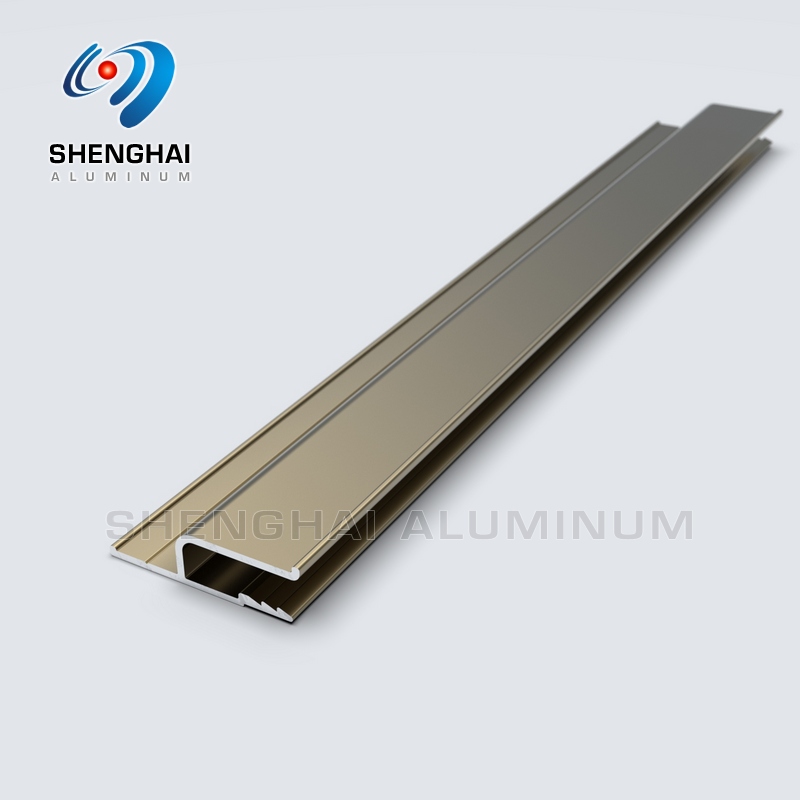

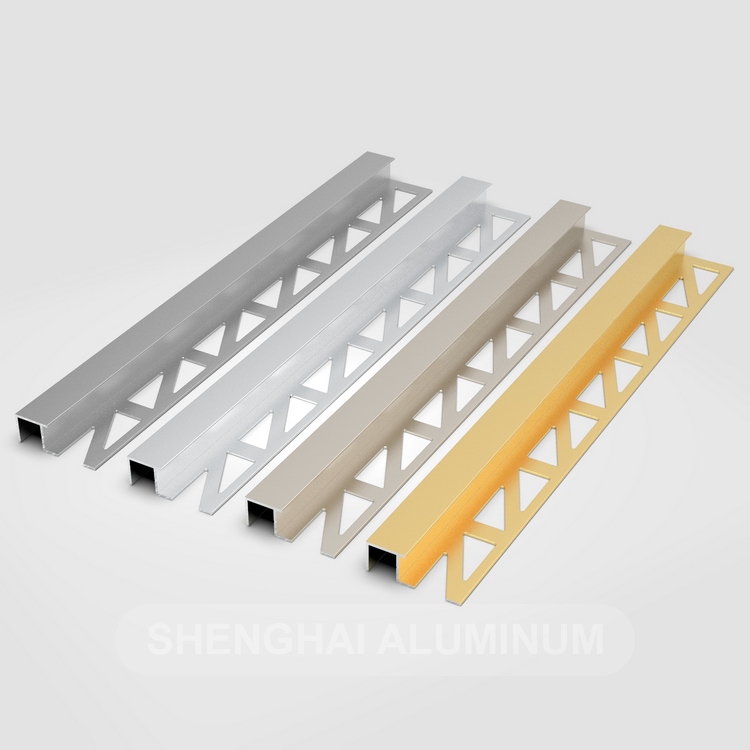

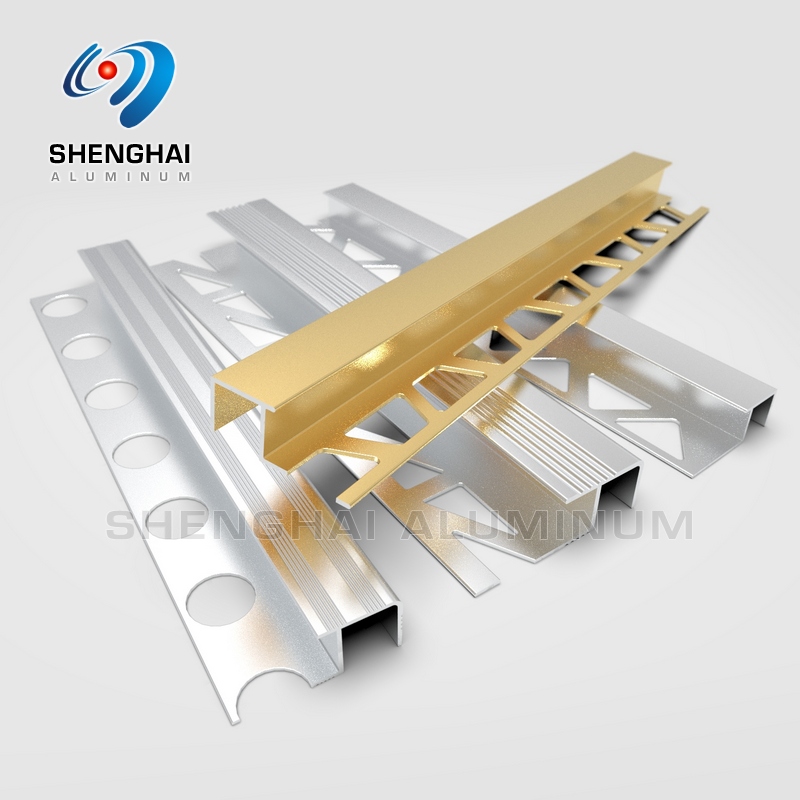

Aluminum trim for tiles is available in a variety of shapes to accommodate different tile configurations and design needs. Some common shapes of aluminum trim include:

Straight edge trim: This is a simple, straight strip of aluminum that is used to finish the edges of tiles installed along a wall or floor.

Bullnose trim: This type of trim has a rounded edge that creates a smooth transition between the tiles and the wall or countertop.

Cove trim: Cove trim has a curved profile that provides a seamless transition between the tiles and the wall or countertop.

Square edge trim: This type of trim has a square profile that is used to create a clean, modern look in tile installations.

Stair nose trim: This type of trim is specifically designed for use on staircases and has a nosing profile that provides a finished edge for the top step.

Pencil trim: This type of trim has a thin, pencil-like profile that is used to create a decorative border or to transition between different heights of tile.

Decorative trim: Decorative trim is available in a variety of shapes and styles and is used to add visual interest and to complement the design of the tiles.

These are some of the most common shapes of aluminum trim for tiles, but there are many other styles available to suit a wide range of design needs. China Shenghai Aluminum can produce all kinds of aluminium profiles, if you are interested, please contact us.