LED lighting aluminum profiles are usually made of 6063-T5 alloy aluminum material, which has excellent processing properties and good strength, hardness and corrosion resistance. At the same time, its small density and high thermal conductivity make it one of the ideal materials for housing LED lights.

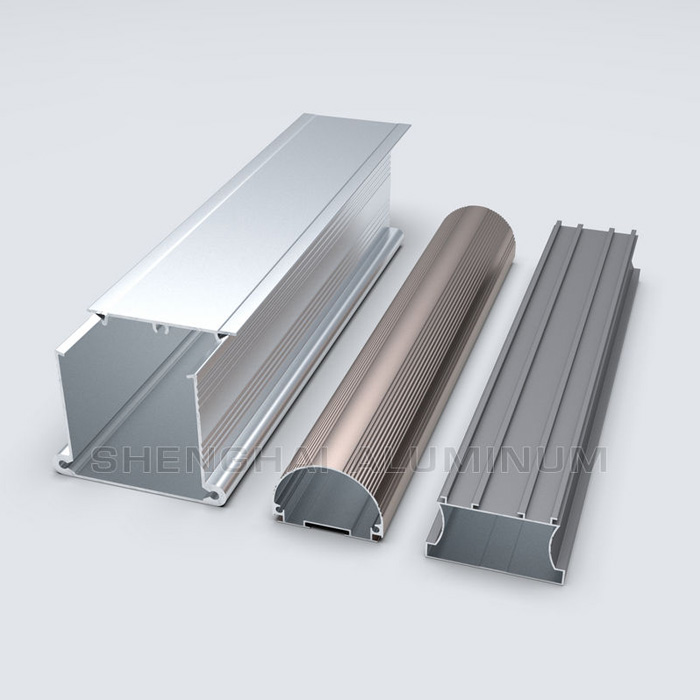

The shape of the extrusion aluminum LED light is usually rectangular or round, which can be customized and processed according to different application requirements to suit different sizes, shapes and installation methods. At the same time, LED light aluminum profiles can be treated with a surface coating or anodizing to improve their surface hardness and corrosion resistance and increase their aesthetic appearance.

LED light: Aluminum profile VS Stainless steel

Compared with stainless steel, high-power LED lights are now generally made of aluminum, including die-casting aluminum, car aluminum, stretch aluminum, etc. Aluminum has the following advantages over steel.

- LED light needs good heat dissipation materials, and aluminum thermal conductivity is much larger than steel.

- aluminum profiles are easy to process. Many stores can be processed easily to take materials.

- aluminum surface has a layer of dense aluminum anodized, which has a good anti-corrosion effect.

- Finally, aluminum is more reasonably priced than stainless steel, which is more cost-effective.

The production process of aluminum profiles includes aluminum ingots through hot melt casting rods, alloy grades including 6061, 6063, 6005, and 6082, through the opening of extrusion dies, heating aluminum rods, dies, hot state extrusion, to get aluminum materials with different cross-sectional shapes, and then aging heat treatment. The production process of aluminum profiles mainly includes four processes: melting and casting, extrusion, machining and surface treatment. Machining includes fine sawing, punching and cutting, CNC number milling, bending and welding, etc. Surface treatment provides vibration grinding, wire drawing, polishing, sandblasting, anodizing, liquid painting, powder coating, electrophoretic painting, wood grain transfer and other processes.

In the design and production process of extruded aluminum LED lighting, factors such as heat dissipation effect, easy installation, beautiful appearance and reliability need to be taken into consideration to ensure that they can meet the needs and requirements of customers in the process of use.