When the heat dissipation is the same, its weight is only one tenth of the cast iron heat sink, one sixth of the steel radiator, and one third of the copper heat sink.

Aluminum heat sink can be used to achieve energy saving, a cost reduction effect. When the heat sink and the heat conduction from the center export the same temperature, 2.5 times higher than aluminum radiator heat sink amount of cast iron sink. And because of the beautiful appearance, the heating cover can be omitted, so that the heat loss can be reduced by 30%, the cost can be reduced to more than 10%, and the weight can be greatly reduced. Another advantage of using aluminum heat sink is that the price of aluminum is only one third of the price of copper.

Effect of corrosion resistant aluminum heat sink, longer life. A solid oxide film can be formed on the surface of aluminum alloy materials, which can be used for a long time in heating water with pH ≤ 9 or in automobile water tanks, while aluminum radiators with special surface treatment can be used in various materials with pH ≤ 12 for a long time.

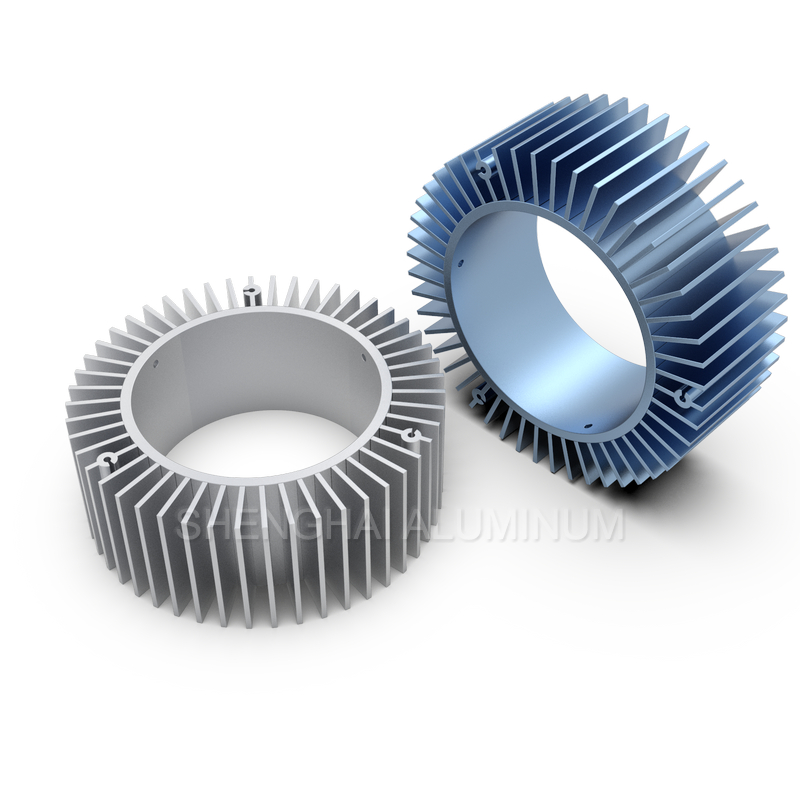

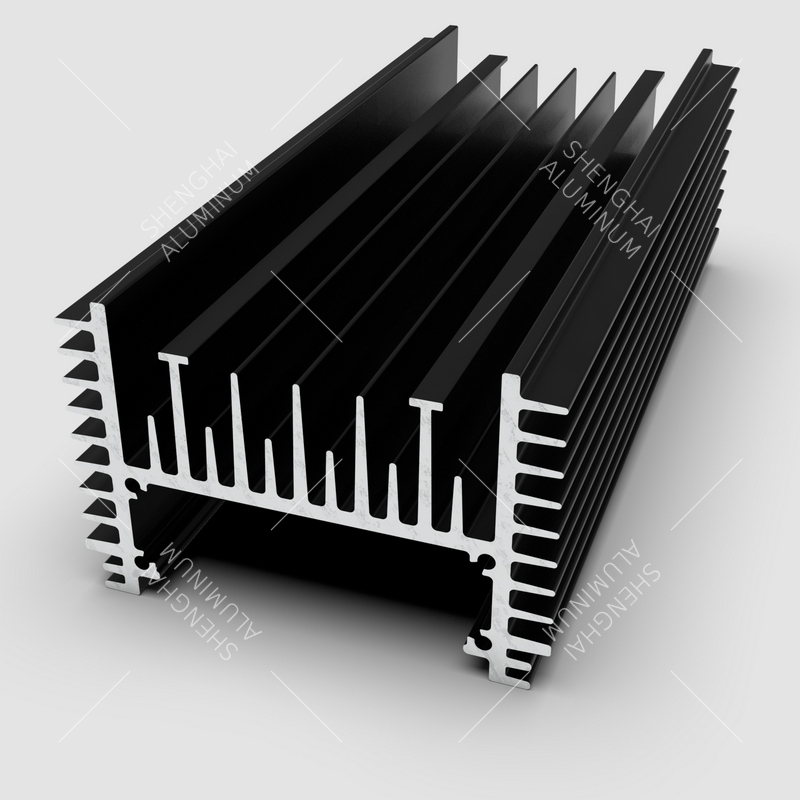

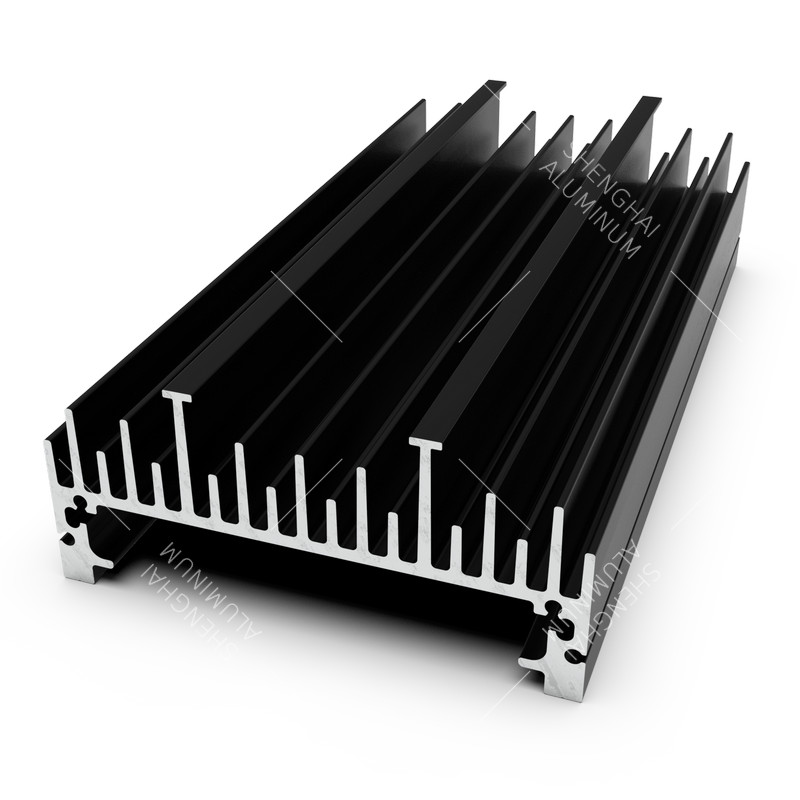

Advantages of aluminum heat sink:

- aluminum radiator that various surface treatments, many varieties, and no solder joints, decorative, aesthetic and durable.

- It is safe to use and bears high pressure. Because the specific strength and specific stiffness of aluminum alloy are much higher than that of copper, cast iron and steel. Even in the case of a thin, also can withstand sufficient pressure, bending force, tensile and impact forces during handling, installation, use, will not damage phenomenon.

- Aluminum alloy material has the characteristics of light weight, which is easy to install and transport.

- Simple installation and convenient maintenance.

For more information, please follow our company website: aluminum heat-sink