T slot aluminum frame is an extension of the industrial aluminum profile that is widely used. It can be used for the manufacture of various equipment supports and load-bearing skeletons. High-quality industrial aluminum profiles are characterized by their light quality and good corrosion resistance. So, what are the characteristics of an industrial aluminum frame made from aluminum slot profile?

T Slot Aluminium Frame

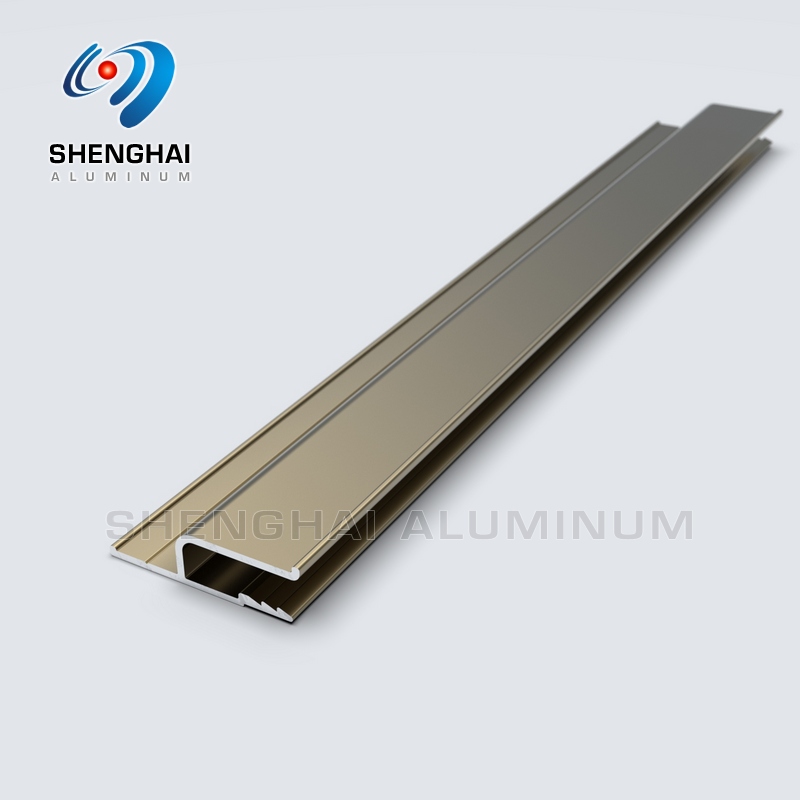

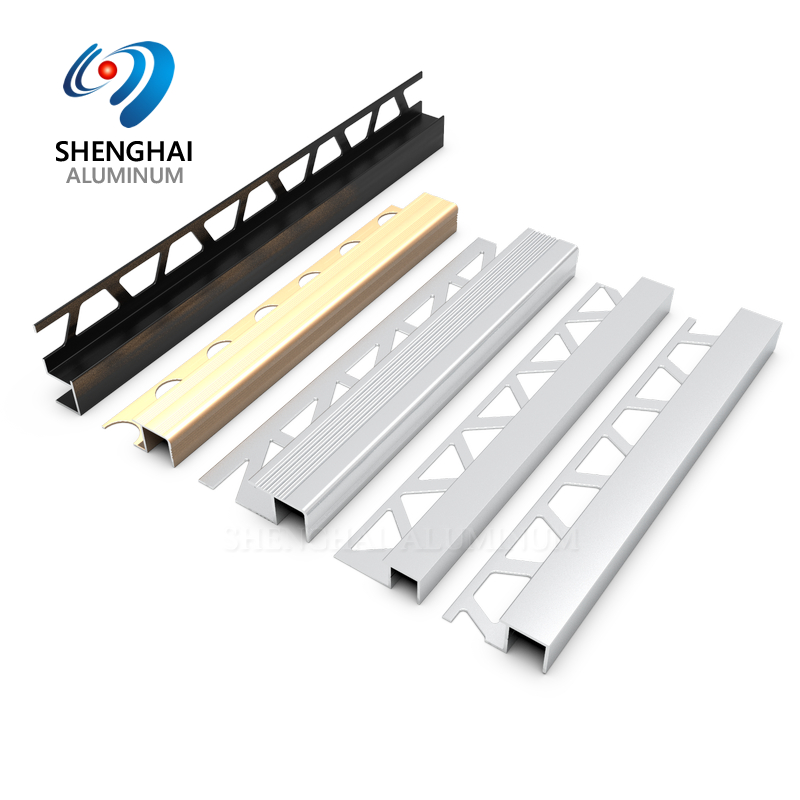

- Reasonable structure and high flatness

A good quality slotted aluminum frame should have a reasonable structure, and the surface should be flat and free from unevenness. Only when these standards are met will the industrial aluminum frame be evenly stressed, have a good service life and avoid the phenomenon of bending and deformation.

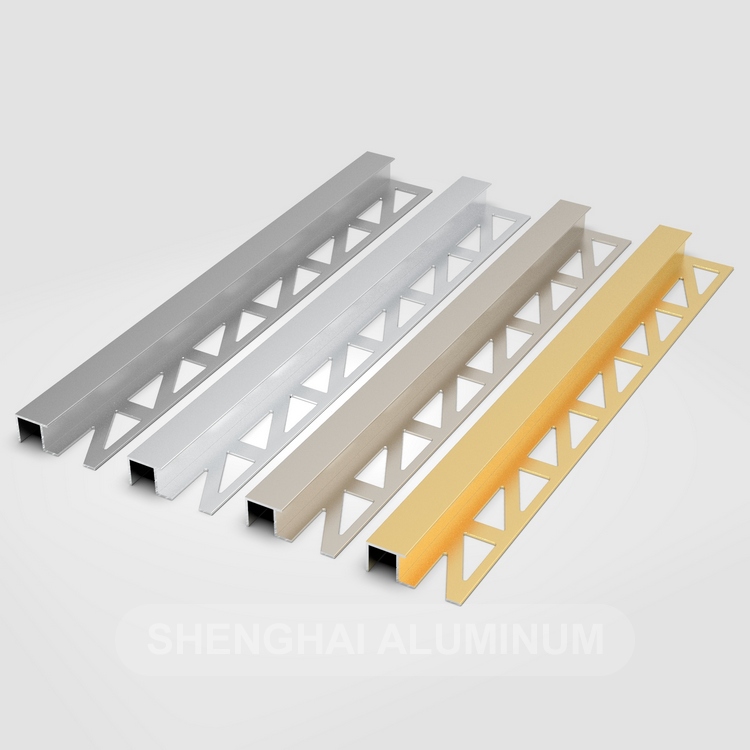

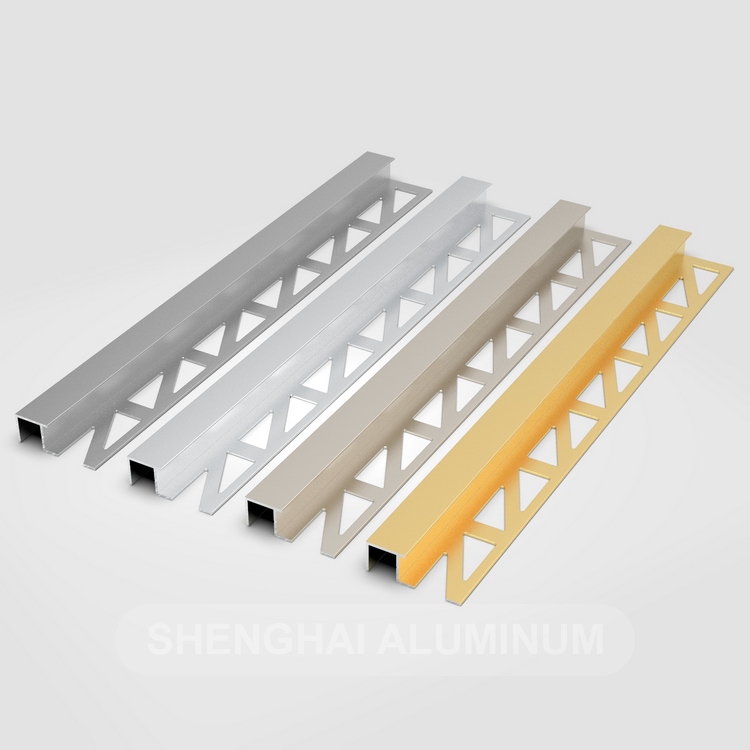

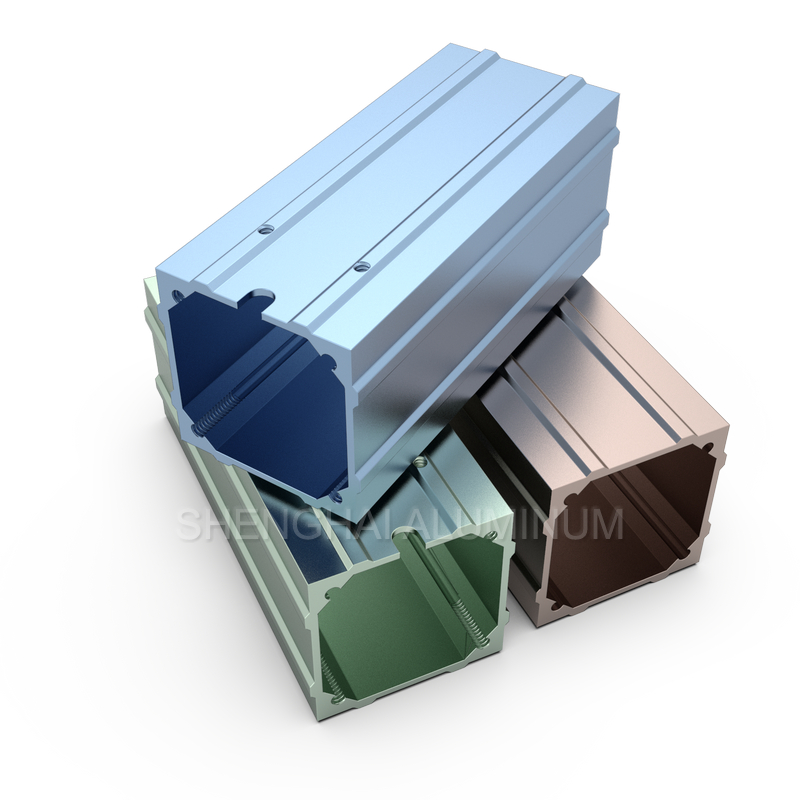

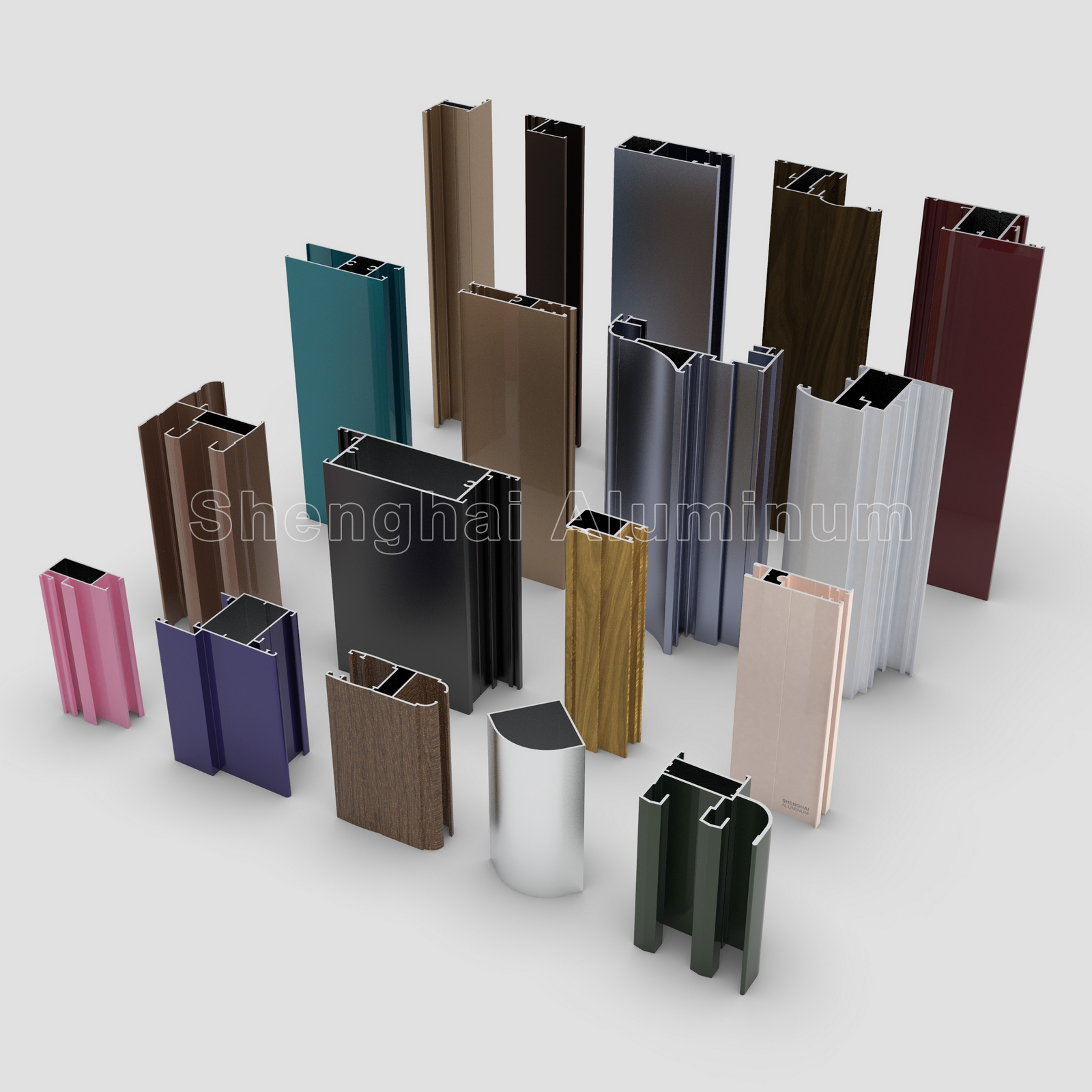

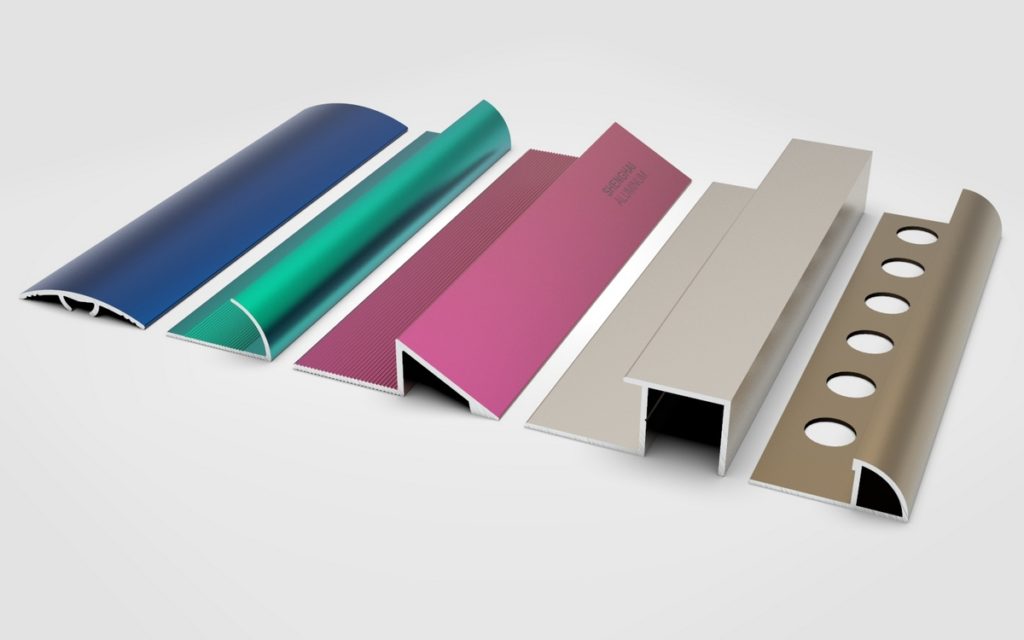

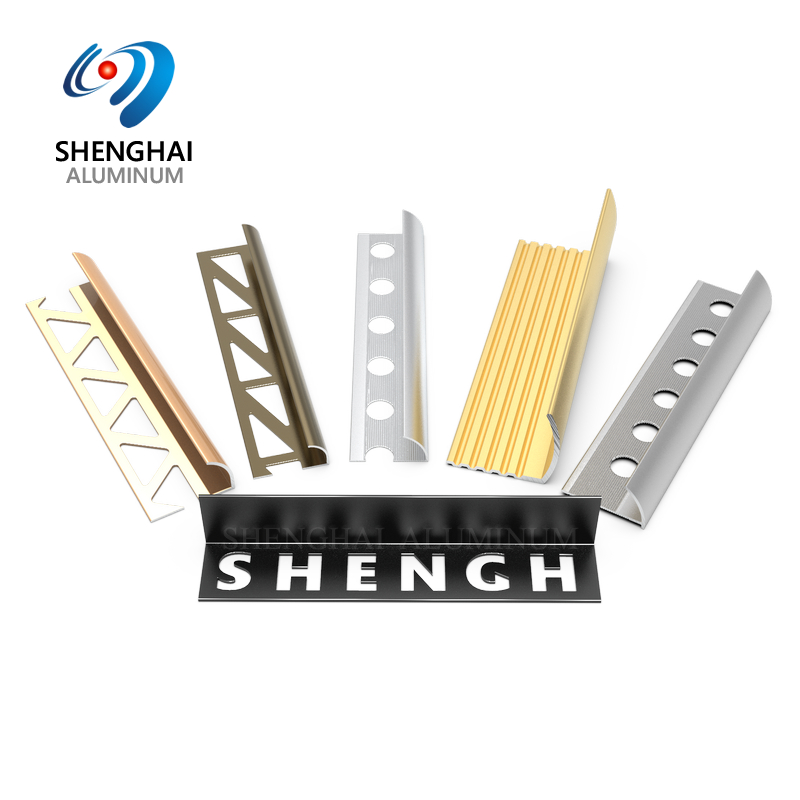

2.Appearance of the color is uniform and beautiful

The overall color of the qualified industrial aluminum frame is uniform, which requires users to distinguish well before purchasing. The good quality industrial aluminum profile frame is usually after the surface treatment; common colors are silver, white, black, gold, stainless steel, etc. If the use of recycled aluminum production of aluminum profile frame is likely to appear on the surface of dark and uneven colour cleaning, the appearance of industrial aluminum profile frame is a beautiful premise is the need to use the quality of qualified aluminum profiles to build.

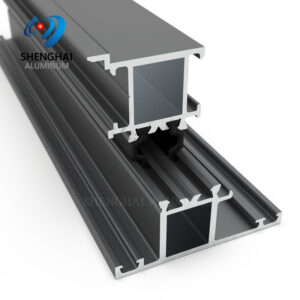

3.Connection parts are precise and no large gaps

Aluminum slot profile frame is generally connected through industrial aluminum profile accessories. It is usually connected using the overall structure. Qualified industrial aluminum profile frames have specific connection parts and small gaps.

4.Stable structure and high safety

A well-built aluminum extrusion t slot frame is safe and stable, does not shake, and has a good load-bearing capacity. Suppose you want to obtain good stability in the initial customization program. In that case, you must remember to choose a suitable aluminum profile type and a reasonable frame structure. You need to regularly check whether the connection parts are loose after the installation is completed.