The commonly used aluminum alloy profiles in China are 6-series aluminum profiles, which 6063, 6061, and 6005 series are used the most in 6-series.

So what is the difference between these three grades of aluminum alloy? Now we have to conduct an in-depth study on it.

The 6-series aluminum alloy are all aluminum-magnesium-silicon alloys, which have the characteristics of good forming performance, good corrosion resistance and high hardness.

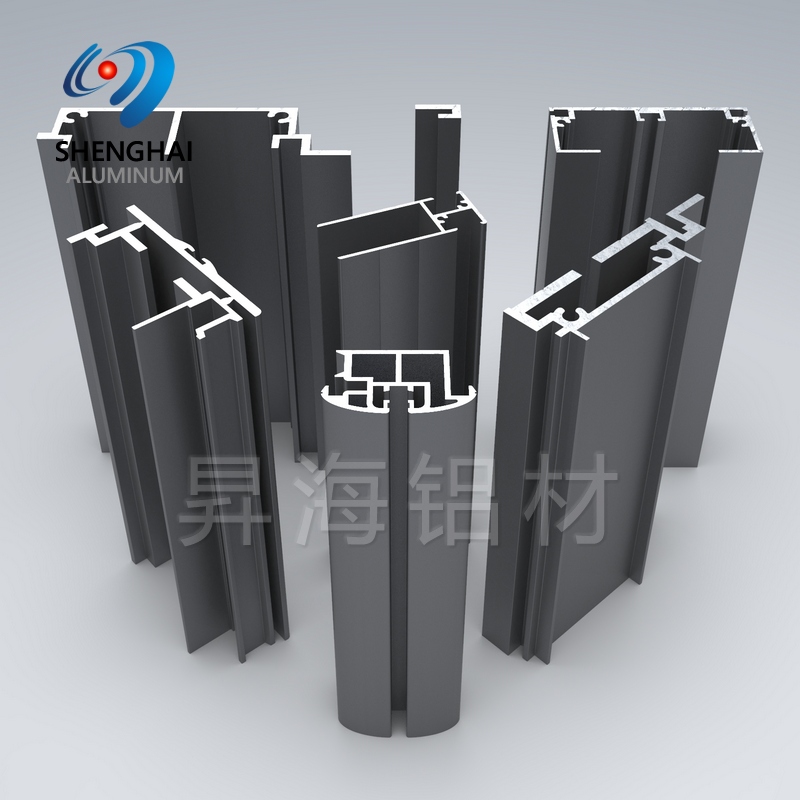

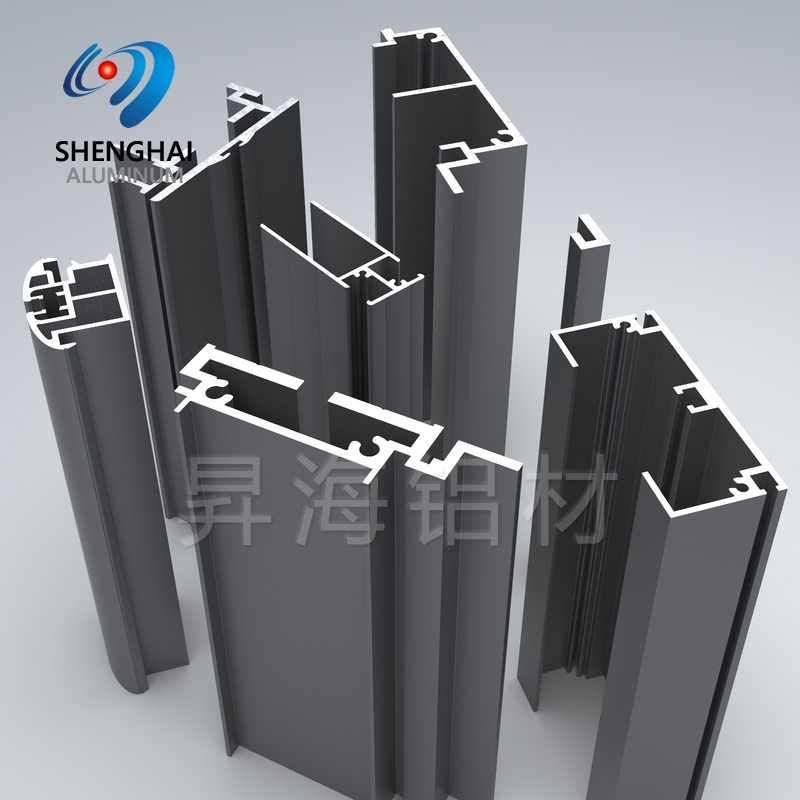

Therefore, they are all suitable for making good use of profiles, but they each have different uses.

Different alloy composition content:

Among them,

The magnesium content of 6005 is 0.4%~0.6%, and the silicon content is 0.6%~0.9%.

The magnesium content of 6061 is 0.8% to 1.2% and a silicon content of 0.4% to 0.8%.

The magnesium content of 6063 is 0.45%~0.9%, and the silicon content is 0.2%~0.6%.

The content of other trace elements is different, so the content of the alloy will cause the difference in performance, strength, and scope of use.

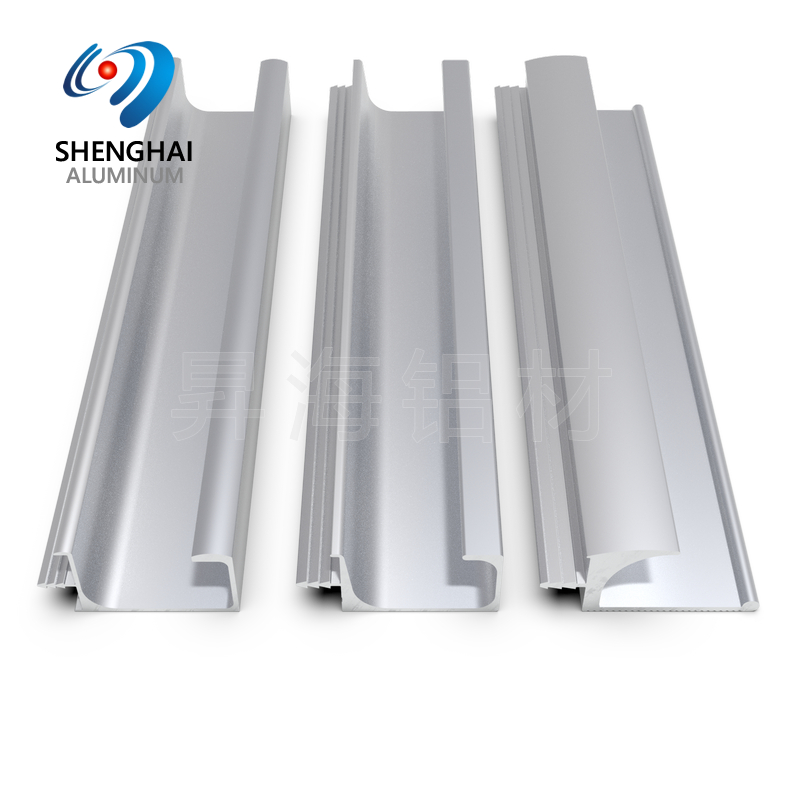

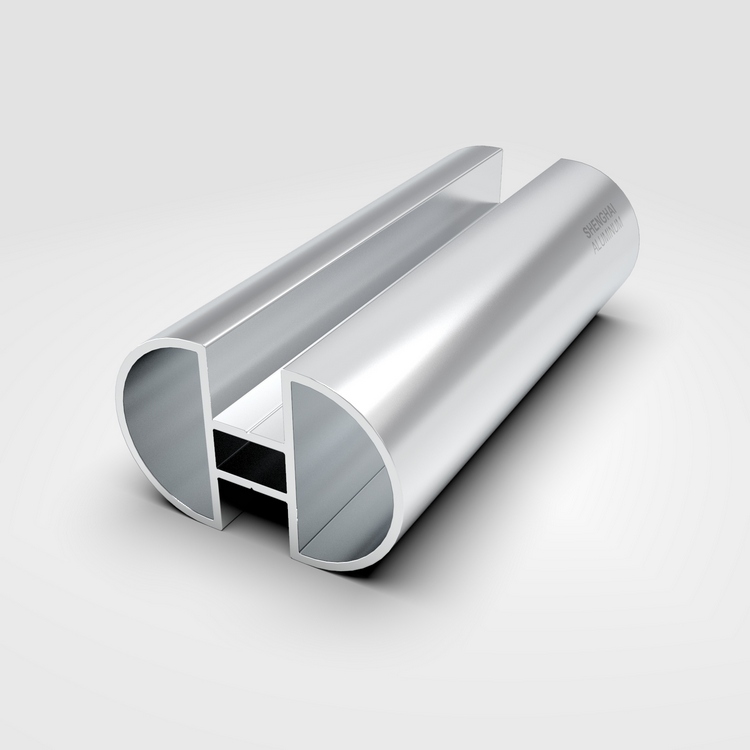

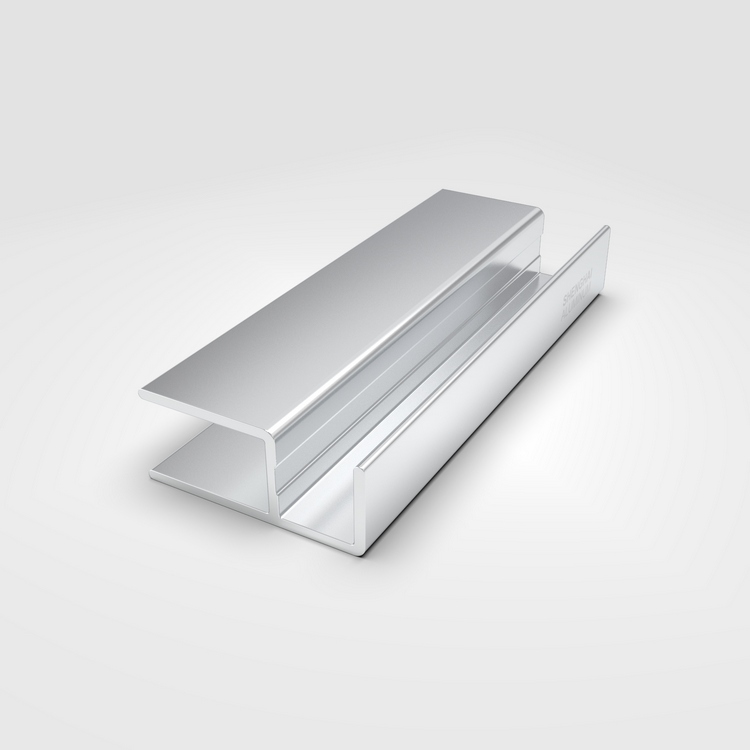

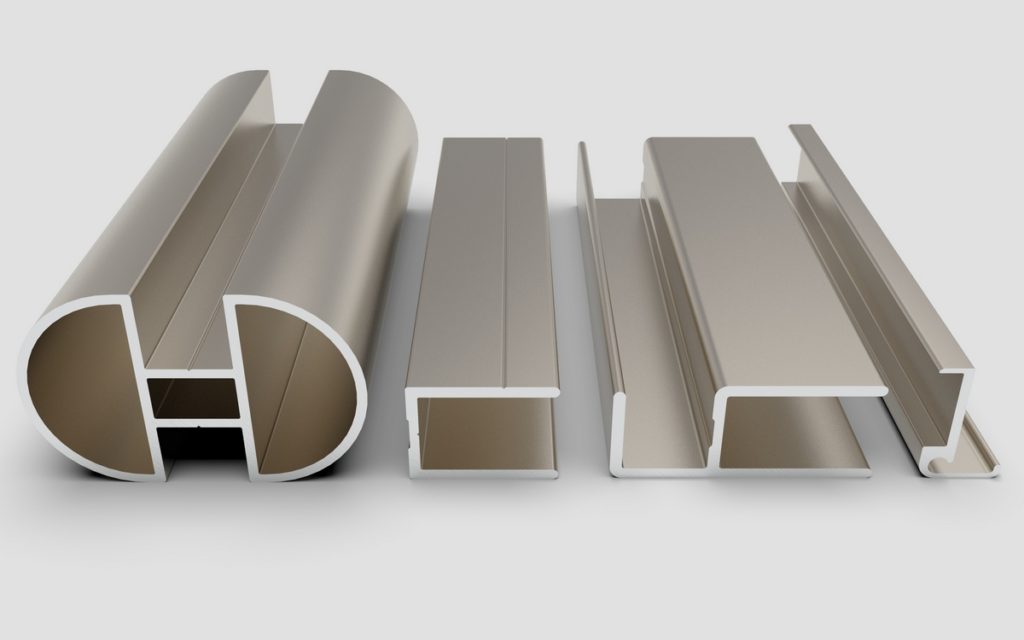

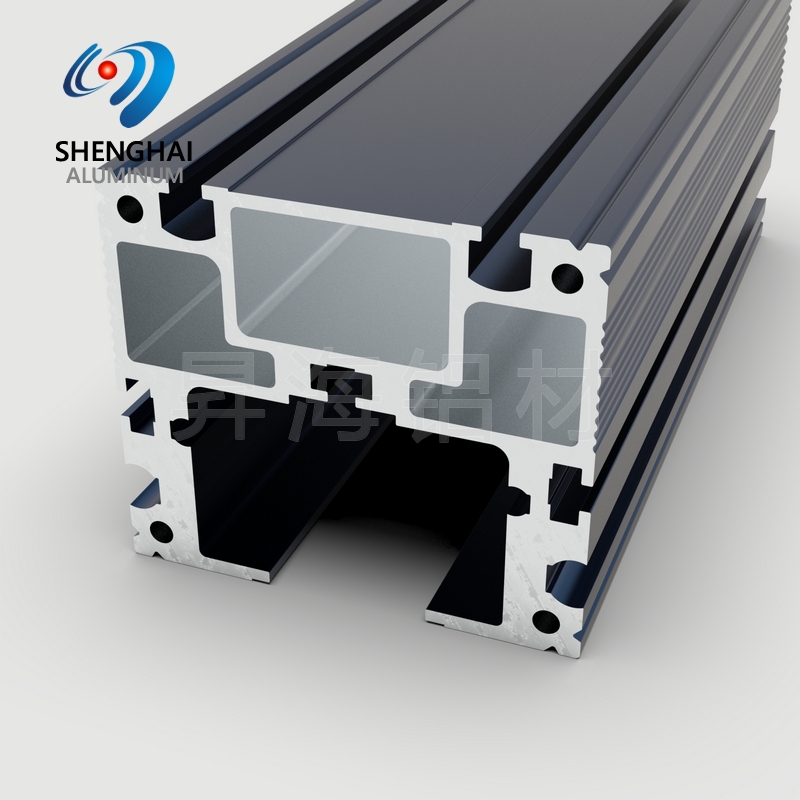

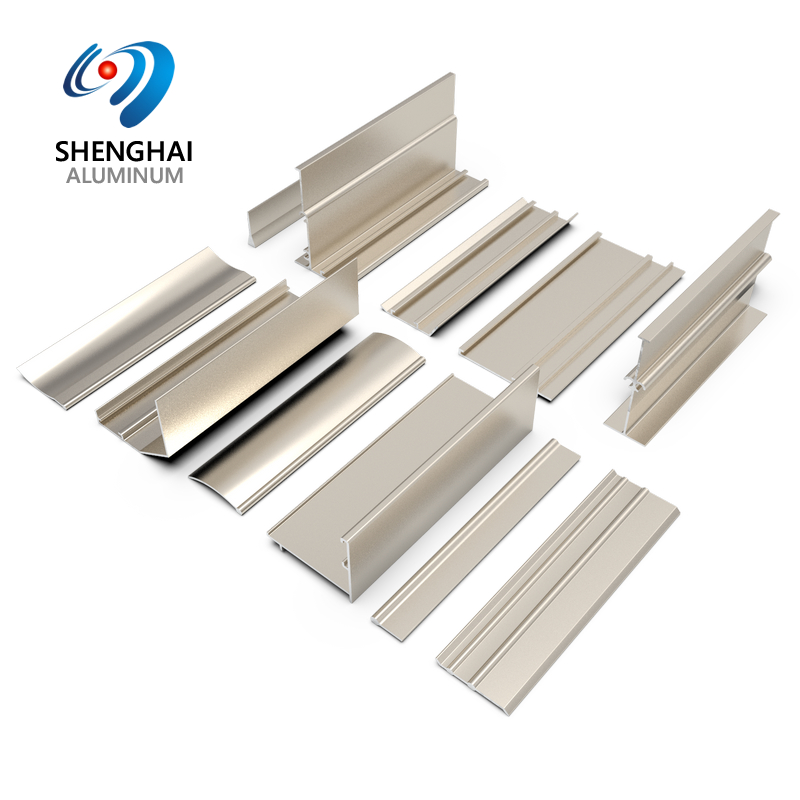

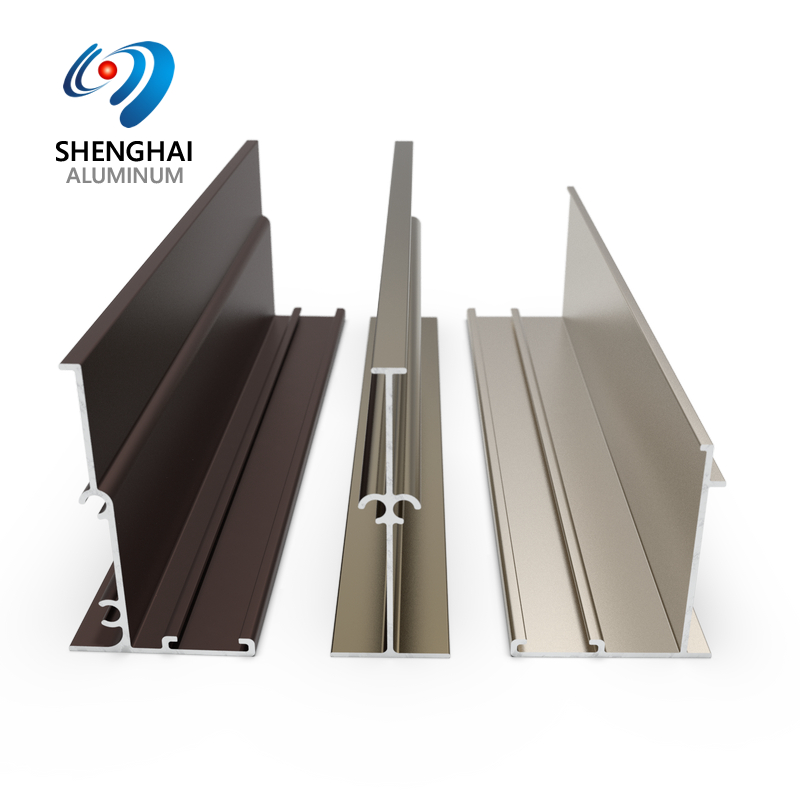

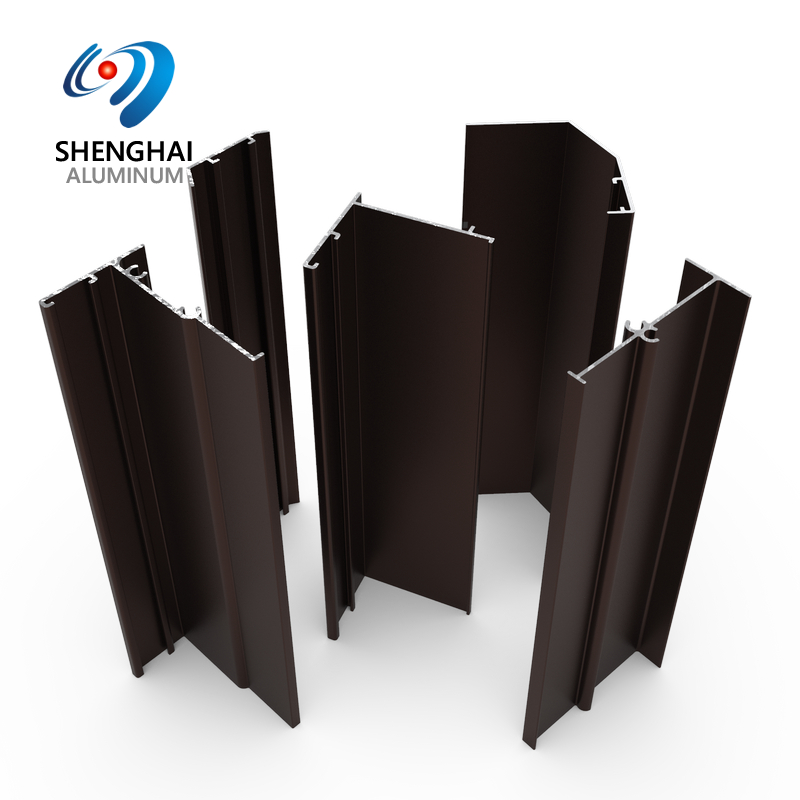

The plastic properties of 6063 aluminum are better than 6061, so most of the extruded profiles use 6063 grades. However, the strength and processing properties of 6063 are not as good as 6061 aluminum. Compared with 6061 and 6063, 6005 aluminum has higher tensile strength and yield strength, and has better fracture toughness. For profiles requiring higher strength, 6005 brand will be used.

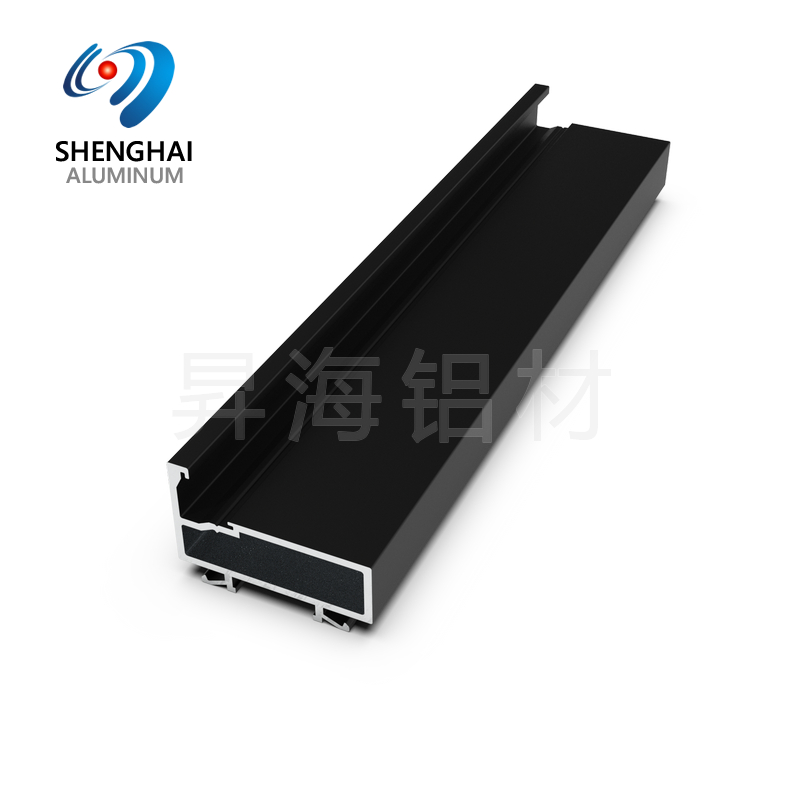

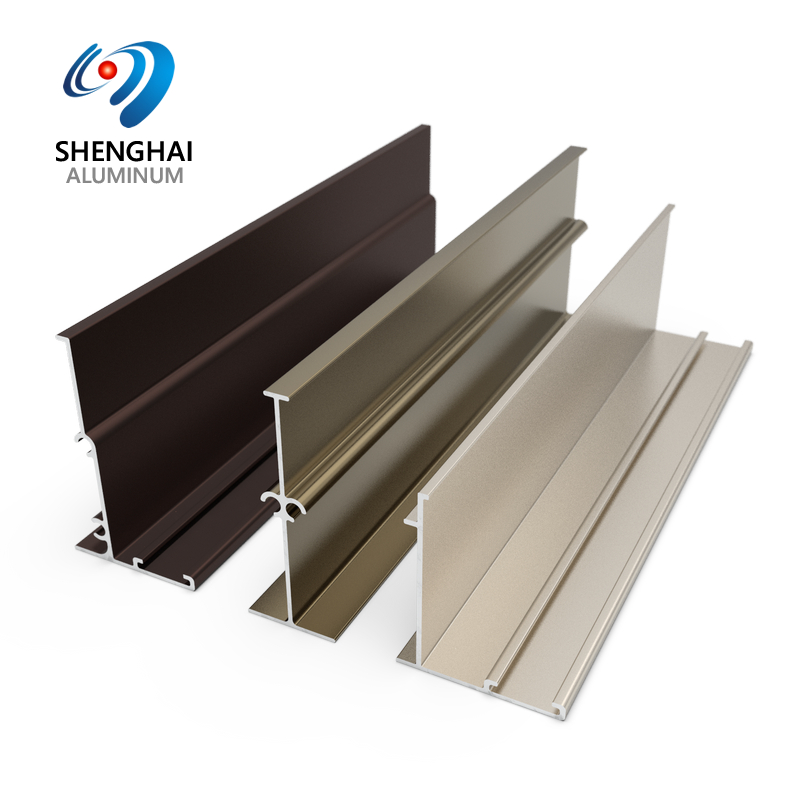

The surface gloss of 6063 and 6061 is better than that of 6005, and 6005 aluminum will be darker. Therefore, 6063 aluminum is more suitable as a decorative material

6061 and 6005 can be made into aluminum plates, but 6063 basically cannot be made into aluminum plates.

6063 aluminum alloy is a kind of aluminum alloy material with extremely strong comprehensive performance, which is widely used in the fields of I industry and construction. 6061 aluminum is mainly used in aerospace, marine equipment, molds, electronic products, corrosion-resistant structures and other fields. 6005 aluminum alloy is often used in structures that require high strength such as ladders and TV antennas.

In addition to the 6 series aluminum alloy profiles, the 7 series also have extruded profiles. The 7 series has higher strength than the 6 series, and the plasticity is not as good as the 6 series, so the production is more difficult and the price is more expensive. The 7 series aluminum profile is mainly used in the aerospace field, also called aviation aluminum profile. We often see so-called “aviation aluminum profiles” in our market, but they are actually 6 series aluminum profiles. Real aerospace aluminum profiles will not be used in the civil market.

For more aluminum profile information, you can go through Shenghai Aluminum official website: Aluminum Profile Catalog