Mechanical lines on the surface of industrial aluminum profiles are one of the main reasons for aluminum profile processing waste, and it is also a difficult problem in the aluminum processing industry.

- The quality of aluminum rod

- The grains of the aluminum rod are coarse, and the surface of the extruded aluminum profile will form a coarse crystal band during extrusion production. The light reflection will form a pattern of light and dark on the surface of the profile.

- Aluminum rod inclusions or segregation, and the segregation Al9Fe2Si2 on the surface of the aluminum rod will also cause the surface texture of the extruded aluminum profile. In addition, the high hardness inclusions in the aluminum rod will scratch the die when the aluminum profile is extruded, and cause stripes on the surface of the extruded industrial aluminum profile.

- Extrusion process

- The squeeze ratio is unreasonable

- Excessive extrusion ratio will squeeze the die. If the extrusion ratio is too small, the deformation of some parts of the aluminum profile will be within the range of the critical deformation. When the aluminum alloy is recrystallized, large grains will appear in the critical deformation. , Aggravate mechanical lines.

- Extrusion temperature

The extrusion temperature will increase as the extrusion speed increases, and the high temperature will cause mechanical lines and even cracks.

- Extrusion speed

Excessively high extrusion speed will tear the surface of the aluminum profile.

- Extrusion die

At present, most of the domestic 6063 grades of industrial aluminum profiles adopt the method of forward extrusion. When the aluminum cast rod passes through the mold under the conditions of high temperature and pressure, it is easy to cause aluminum to stick to the mold. As a result, the aluminum profile may be adhesive, tear, and strained.

- Mold material

- Die steels of different grades will have different resistance to metal adhesion. At present, H13 steel is the best die steel material.

- Mold surface treatment method

The adhesion and wear of aluminum alloy occur on the contact surface of the mold and the aluminum material, so the contact surface of the mold should be nitridated, which can effectively improve the hardness, wear resistance and fatigue strength of the contact surface of the mold.

- The nature and state of the mold sizing belt

The nature and condition of the die surface sizing belt have a very large impact on the surface roughness of extruded aluminum products.

- Mold structure

The structure of the die bridge and the height of the welding chamber have a relatively large impact on the formation of mechanical lines on the surface of industrial aluminum profiles.

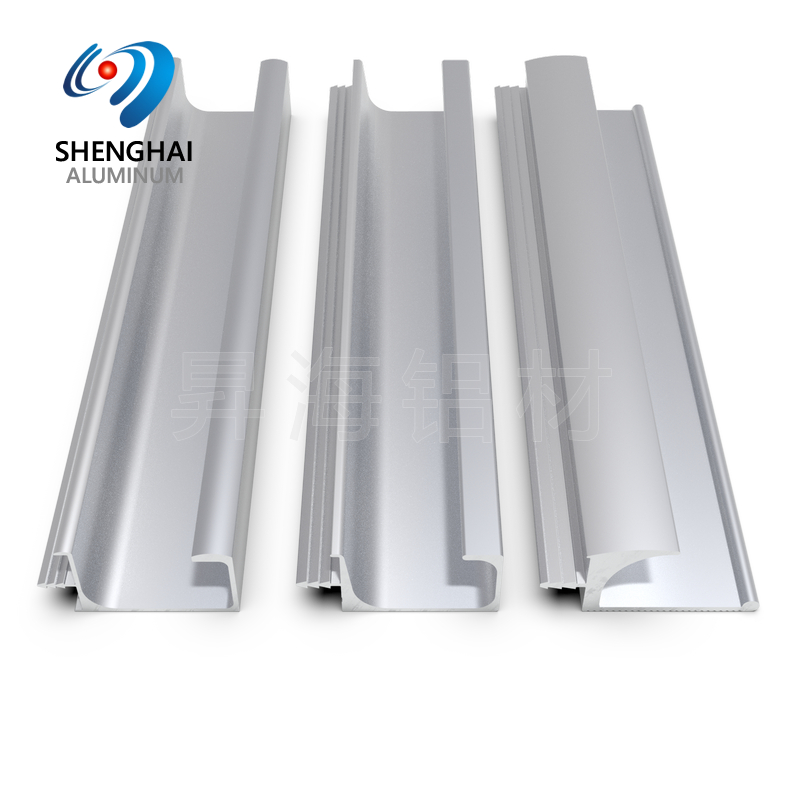

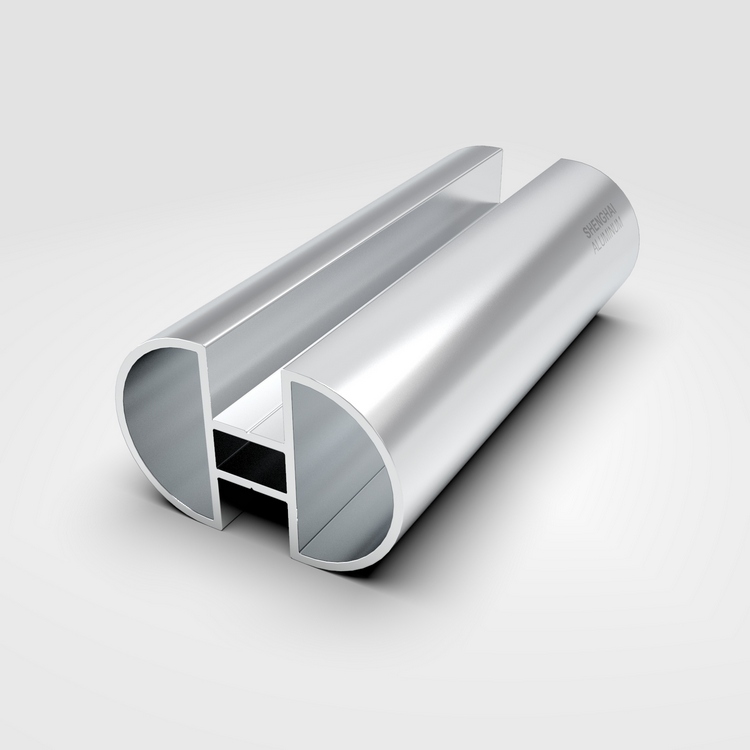

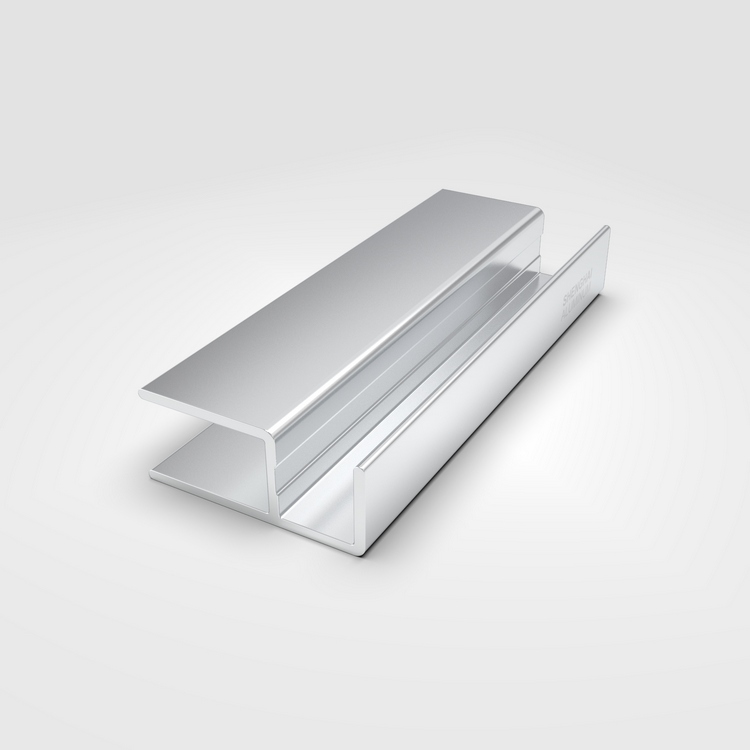

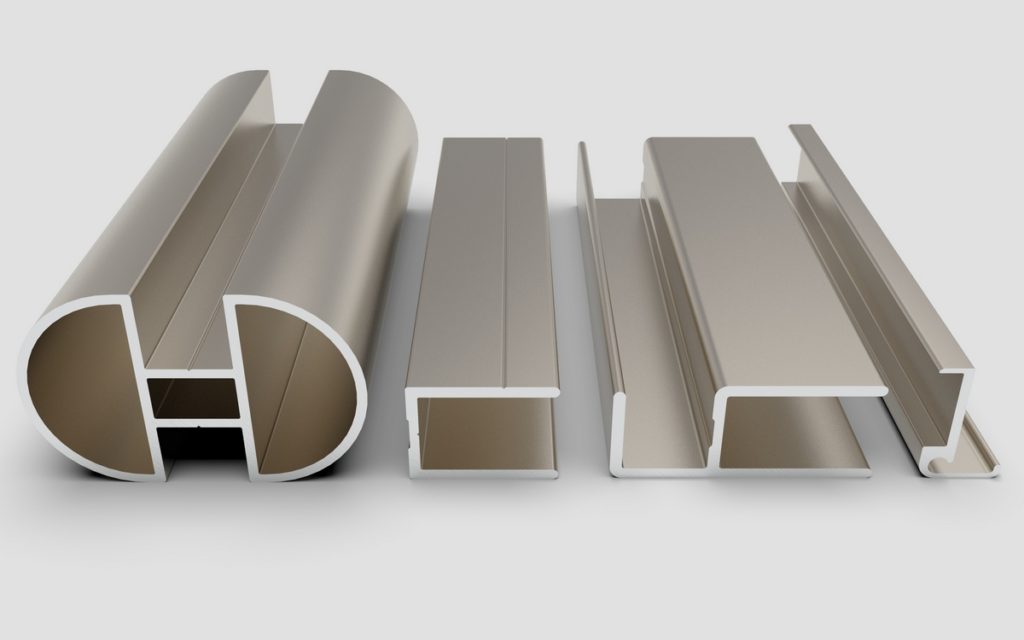

For more aluminum profile information, you can go through Shenghai Aluminum official website: Aluminum Profile Catalog