Nowadays, purchasing agents from all over the world come to China to look for aluminium profile manufacturers. Because they know that China is the world’s largest producer of aluminium profiles. Although there are many aluminium profile manufacturers in China, finding a reliable one is not easy.

In fact, for many buyers, the most troublesome issue is not negotiating prices, but rather the fear of not being able to find reliable aluminum profile manufacturers. The samples may look high-quality and shiny, but when it comes to actually placing orders and producing the products in large quantities, they turn out to be full of flaws. The promised delivery dates are constantly delayed, ultimately affecting the progress of the entire project. Even the aluminum rods are passed off as inferior quality. These frustrating problems should have been encountered by every buyer.

Everyone knows that China is the world’s largest producer of aluminum profiles. Then many people will ask: Are Chinese aluminum profile manufacturers reliable? Actually, this question itself is flawed. Reliable aluminum profile manufacturers can help you solve problems, control costs, ensure delivery, and reduce cooperation risks. Unreliable ones will only cause trouble for you. So, how can you find a reliable aluminum profile manufacturer?

First and foremost, the quality of aluminium profiles lies in the aluminium rods. This is a point that many purchasers tend to overlook. Recycled aluminum rods have many impurities and uneven composition. The profiles made from it are not only prone to cracking when bent but also exhibit problems such as color differences and paint peeling during surface treatment. What’s even more fatal is that the mechanical properties of recycled aluminum are unstable. It may deform during subsequent installation and use, resulting in ongoing after-sales issues.

Reliable manufacturers will insist on using high-quality primary aluminum rods, such as those with the industry-recognized 6063-T5 and 6061-T6 as the base materials. This type of aluminum rod has a uniform composition and stable performance, laying a solid foundation for high-quality profiles. We can also provide material inspection reports upon the purchaser’s request. This is solid proof that the report is far more genuine than empty talk.

Similarly, the mass-production capacity for non-standard cross-sections should also be closely examined. In projects, personalized demands and custom-made profiles with special arcs are very common. This is the place where one is most likely to fall into traps. The sample production is qualified, but the mass production fails. When making samples, small factories will use manual grinding to create perfect samples. However, during actual mass production, mold precision is insufficient, production rhythm is chaotic, and product dimensions deviate. It was simply impossible to adapt to other components, and in the end, rework was necessary, which affected the project’s progress.

A reliable manufacturer will control precision from the mold source and ensure cavity size and arc curve through CNC precision processing. At the same time, it should implement standardized mass-production controls, verify cross-sectional dimensions, arc tolerances, and wall thickness uniformity, and only start mass production after confirming that they meet the standards. More importantly, reliable manufacturers maintain a balanced production rhythm and will not sacrifice quality control to meet large orders at the expense of non-standard orders. Even if the construction period is tight, no process will be omitted to ensure the uniformity of each product batch.

There will be many problems with the delivery time and after-sales service. For instance, during peak seasons, many small factories, with their orders piling up, tend to delay delivery dates at will, disrupting the progress of the entire project. After-sales issues have become even more serious. For instance, some purchasers have encountered problems with the clips being too small to install. However, the supplier refused to admit it, insisting that the delay was due to improper installation, which directly delayed the project’s progress and caused significant losses.

Reliable manufacturers never hesitate in these two aspects. The delivery date will be set in advance with a clear production schedule. Even during peak seasons, on-time delivery can be guaranteed by rationally allocating production capacity. And proactively synchronize the production progress with the purchasers. In terms of after-sales service, once it is confirmed that the problem lies with the production end, their first reaction is not to defend themselves. Instead, it is to address the issue of initiating replacement or supplementary issuance, prioritizing the project’s progress.

So, are the aluminum profile manufacturers in China reliable? Whether it is reliable or not depends on who you ultimately choose. The real challenge is not to judge a country’s overall industrial reliability, but to screen for reliable partners within its industries.

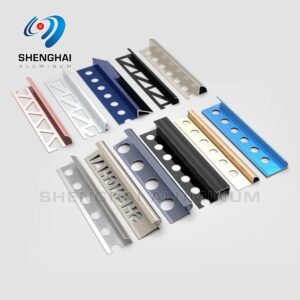

Just like Shenghai Aluminum, a professional manufacturer deeply engaged in aluminum profiles. Our products span multiple categories, including door and window profiles, decorative profiles, curtain walls, and industrial profiles. Possess the capability to provide full-process solutions from design support to production and delivery. If you are looking for a long-term, stable aluminum profile partner, please visit https://www.shenghai-alu.com/ to learn more about our products and case studies.